Case Studies

-

SolMotion combines AI and vision-guided robotics for precise body panel sealing, enhancing quality and efficiency in automotive manufacturing.

-

AccuPick + SolScan enhance bin picking for a European auto parts manufacturer, cutting cycle time to 1.6 seconds and boosting efficiency with rapid AI training.

-

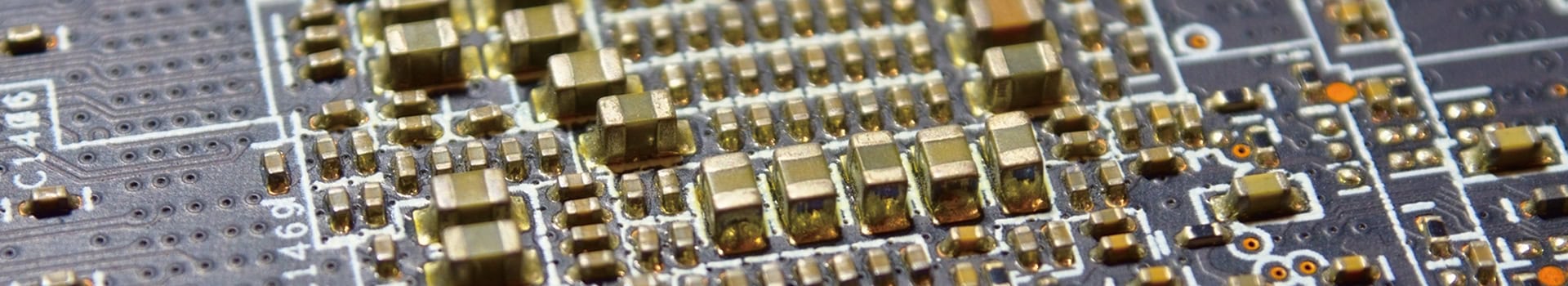

SolVision AI enhances Multilayer Ceramic Capacitor (MLCC) defect detection, reducing false rejections and improving quality control in electronics production.

-

SolVision enhances cookies quality with AI-powered quality inspection, ensuring consistent appearance and high detection accuracy in snack food production.

-

SolVision AI enhances defect detection in metal gaskets, improving inspection efficiency and ensuring high-quality gasket performance.

-

SolVision deployed for woven fabric defect detection achieves precise defect identification in textiles using Solomon’s rapid AI vision technology.

-

SolVision utilizes deep learning technology for enhanced surgical mask inspection, ensuring accurate defect detection and improved quality control.

-

SolVision’s AI and OCR technology enhances Tire Identification Number inspection, improving accuracy, efficiency, and quality control in tire production.

-

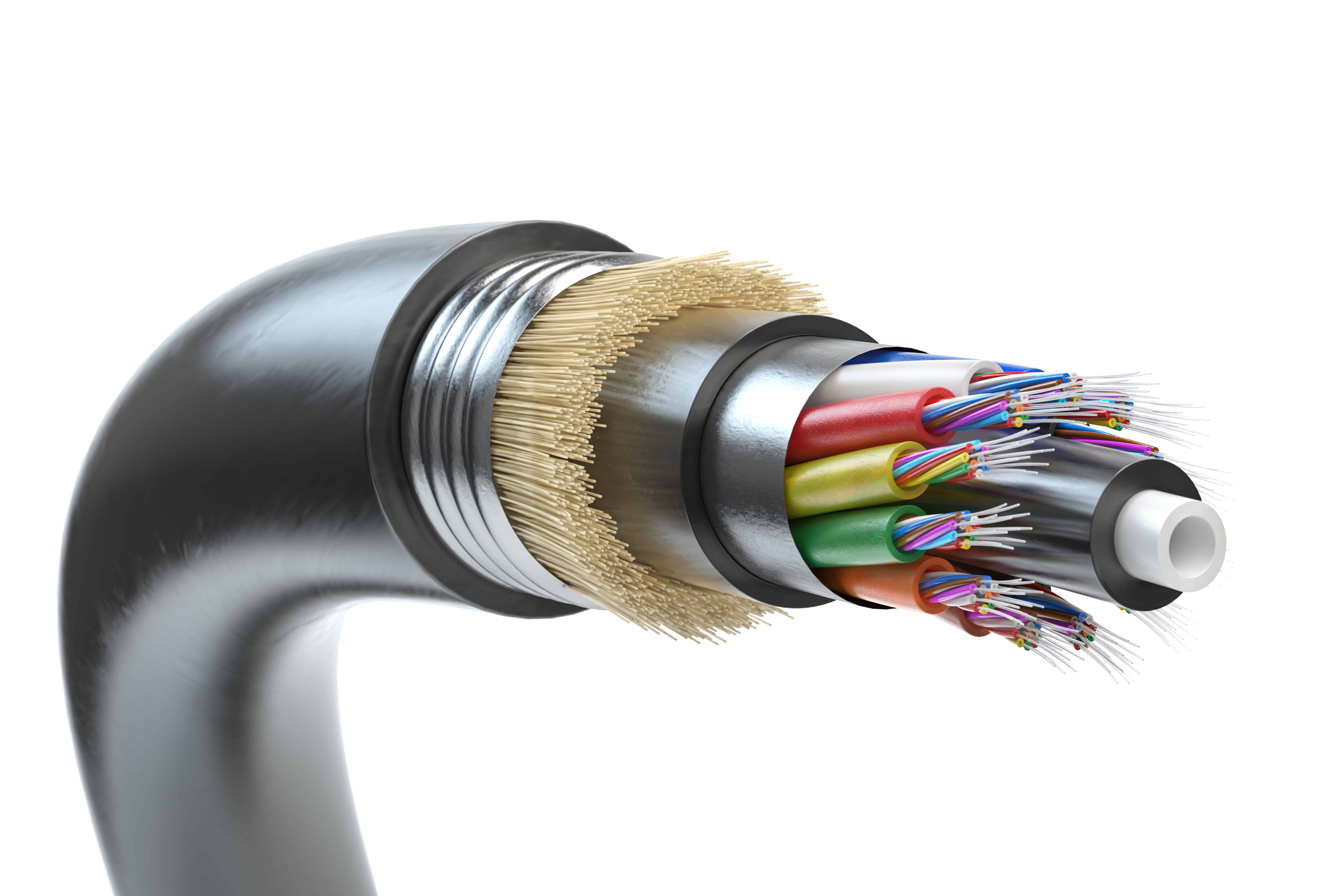

SolVision AI enhances cable defect detection, improving cable insulation quality control, inspection accuracy, and production efficiency for wires and cables.