Semiconductors

-

Explore how META-aivi optimizes waste management with AI, reducing errors and avoiding contamination while enhancing the efficiency of plastic parts recycling.

-

Machine vision is utilized to perform Optical Character Recognition (OCR). This information is sent to the cloud to create an inspection report, allowing plant operators to easily monitor facility inspection through mobile devices.

-

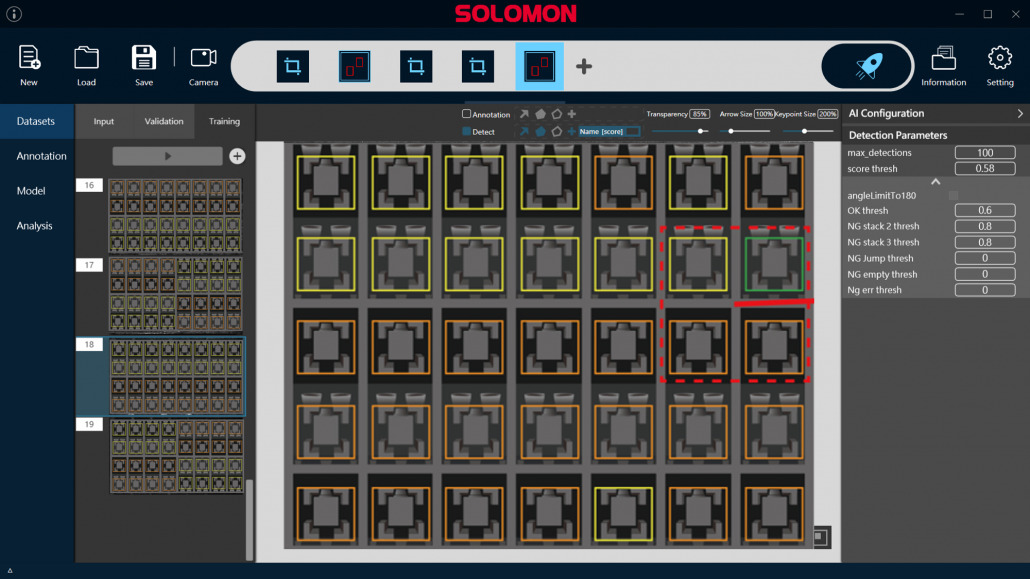

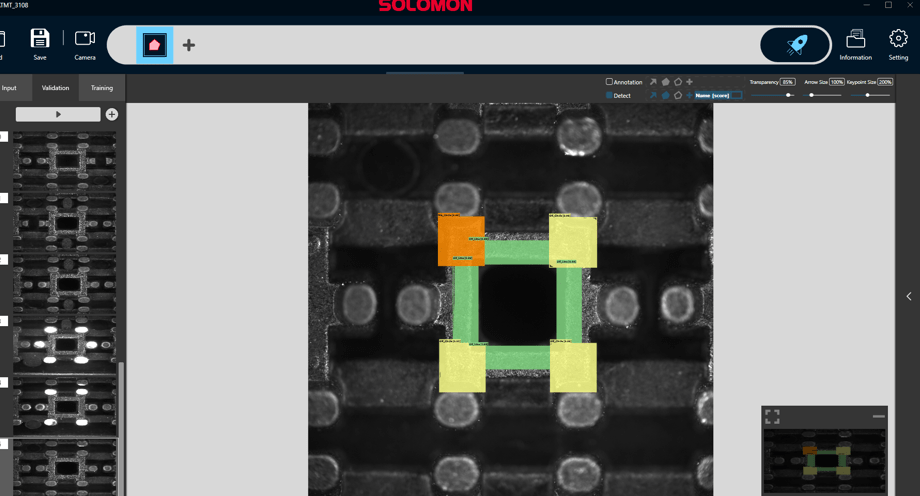

SolVision employs AI to enhance IC tray inspection, ensuring precise detection and elevating quality assurance standards in the semiconductor industry.

-

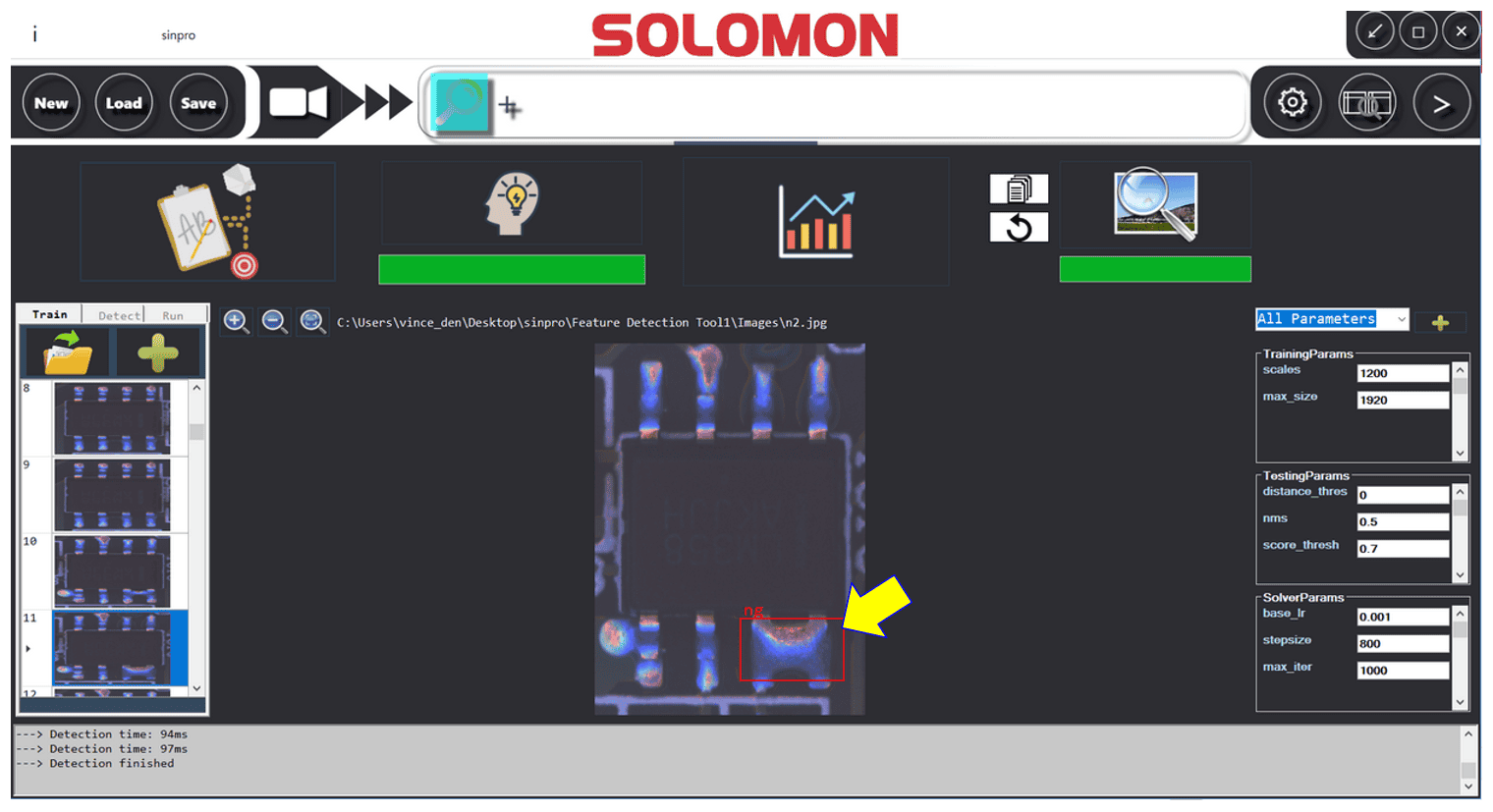

Using SolVision’s AI Inspection Solution, minute defects such as fine scratches can be located and marked on sample images to train the AI model.

-

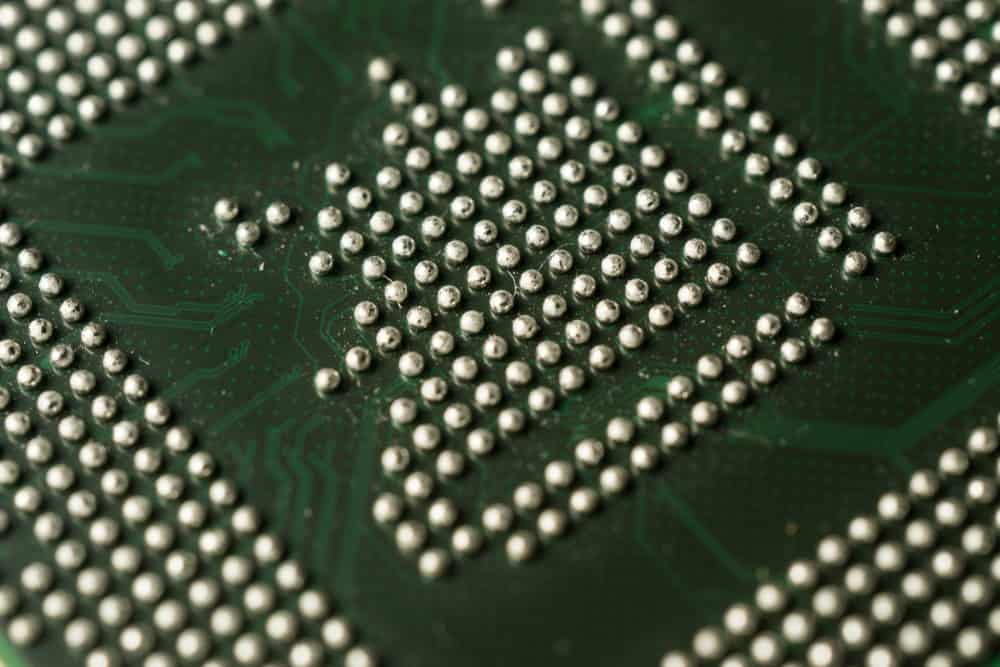

SMT is a critical soldering process in the electronics industry. SolVision detects defects on PCBs which are known to have numerous small, complex components.

-

SolVision AI detects BGA soldering defects with precision, enhancing defect detection, inspection accuracy, and quality assurance for manufacturers.

-

Using SolVision’s AI Inspection Solution, minute defects such as fine scratches can be located and marked on sample images to train the AI model.

-

Solomon SolVision’s Feature Detection tool first learns the position of the tray, then performs OCR with more flexibility than AOI systems.

-

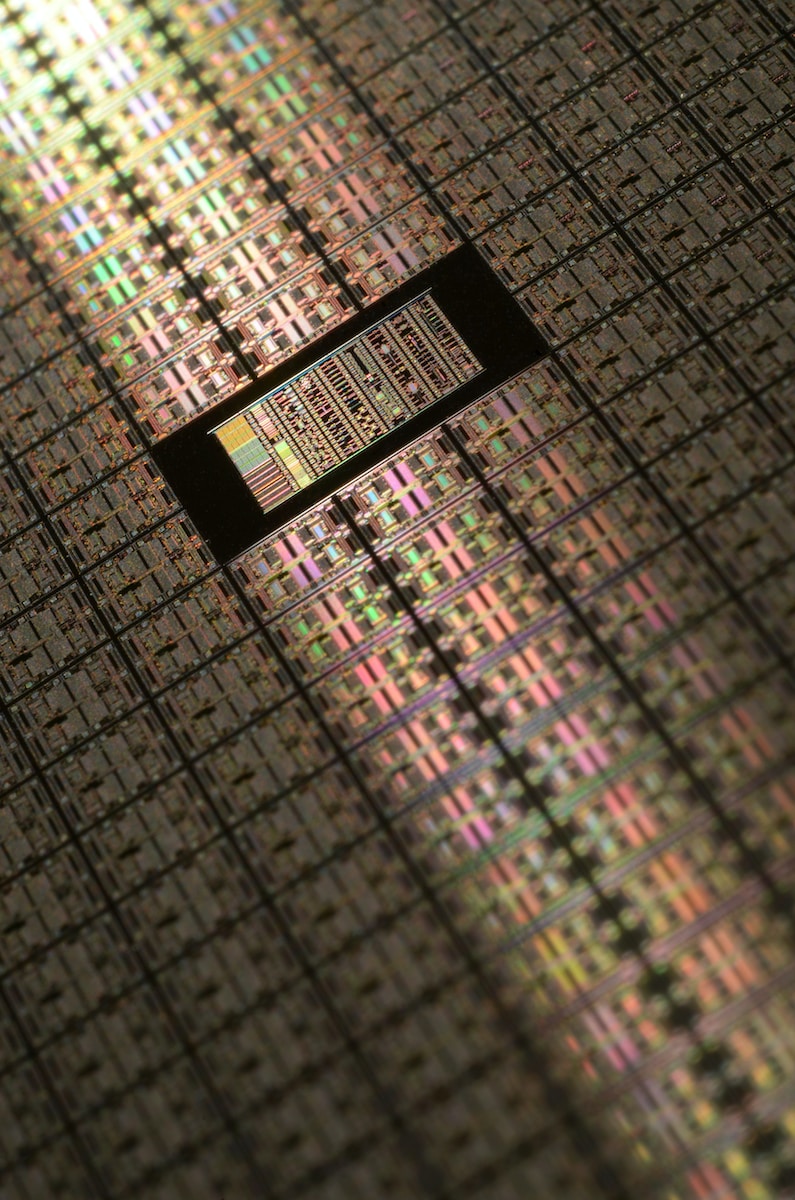

Automated defect detection with artificial intelligence. Visual Inspection of Semiconductor Carrier Trays.