Defect Detection

-

SolVision, Solomon’s AI vision system, enhances bobbin yarn defect detection with superior inspection accuracy, improving yarn quality and reducing downtime.

-

SolVision uses AI for precise car paint defect detection, enhancing quality and efficiency in automotive manufacturing for a leading car manufacturer.

-

SolVision ensures a flawless 100% defect detection rate in just 49 milliseconds per bolt, addressing reflective surface challenges and eliminating false negatives.

-

META-aivi transforms cable inspection with AI, ensuring precision in recognition, classification, and defect detection for efficient electronics manufacturing.

-

AI models can be trained and uploaded into the system for qualified welding points. This enables AI inspection of welded sections using AR glasses or a tablet device to quickly recognize defective welds.

-

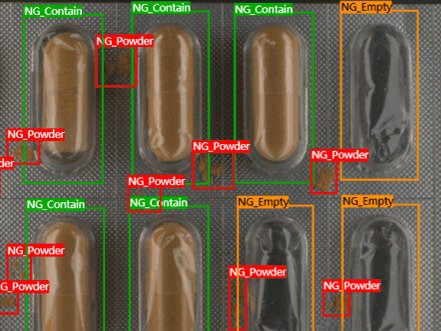

SolVision transforms blister pack inspection, overcoming reflective material challenges to improve accuracy and efficiency in pharmaceutical production with AI.

-

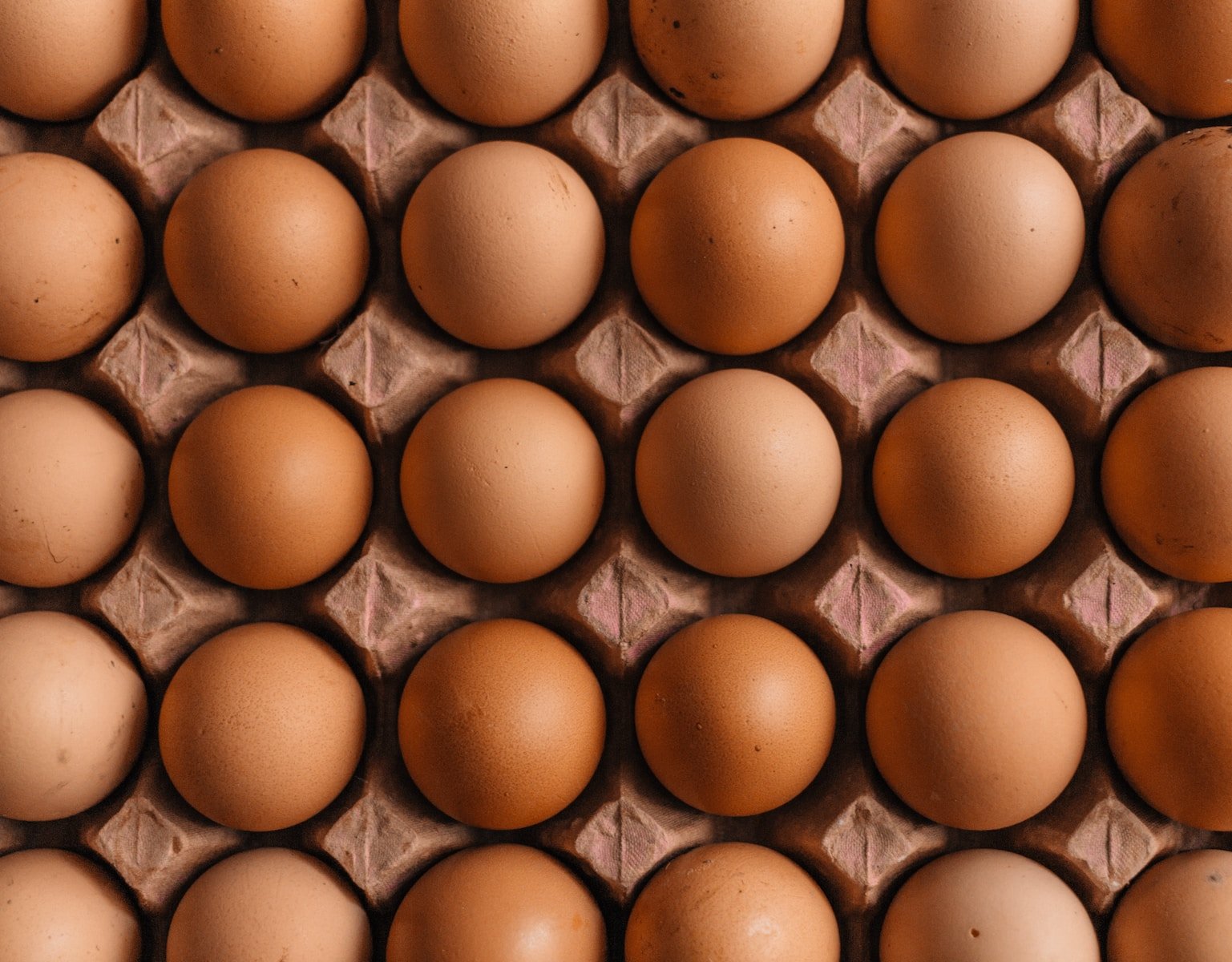

SolVision AI recognizes defects and categorizes eggs, enabling automated egg quality inspection for enhanced food safety and quality control.

-

SolVision enhances PCB inspection efficiency and accuracy by identifying defective PCB components in real-time through AI vision and advanced image processing.