Electronics

-

Solomon’s AccuPick and SolScan technology enable accurate component orientation identification, facilitating precise positioning, while AccuPick’s ROS Motion Planning ensures collision-free picking.

-

Using AR glasses and our easy-to-operate wearable AI, operators are able to accurately identify PCB components and verify that they have been placed correctly.

-

SolMotion offers precise and continuous laser marking with AI-based 3D scanning technology, enabling real-time part positioning for robots to identify and mark objects accurately.

-

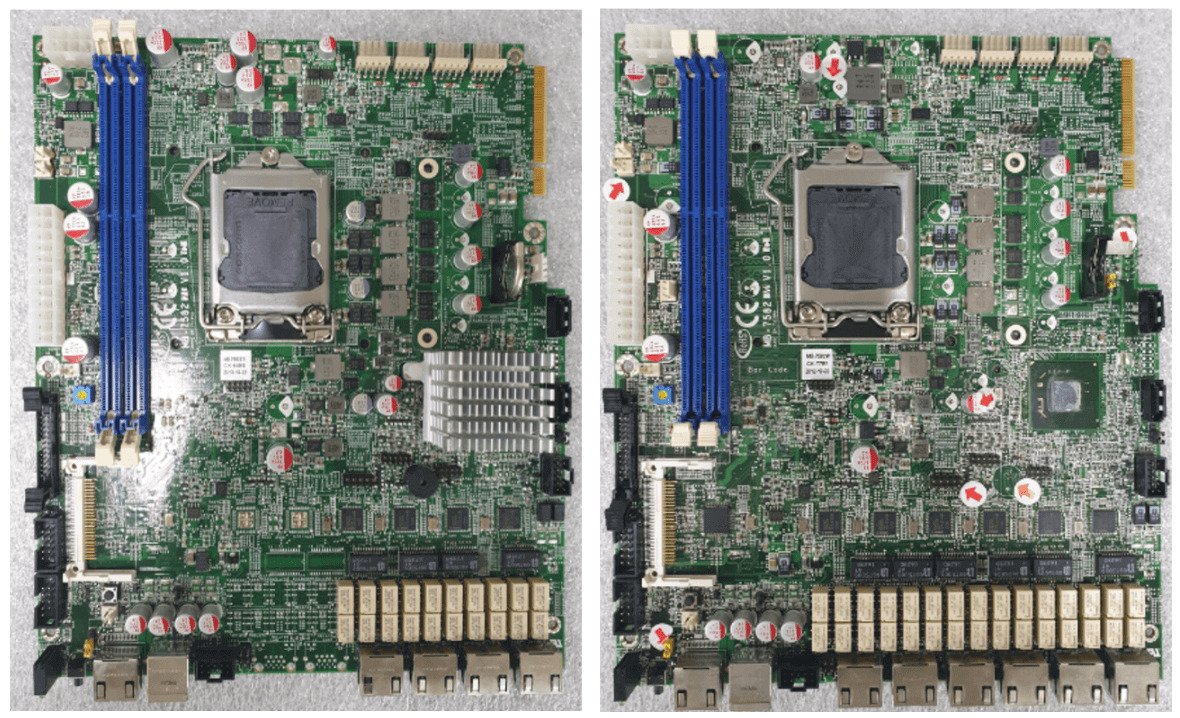

SolVision enhances PCB inspection efficiency and accuracy by identifying defective PCB components in real-time through AI vision and advanced image processing.

-

SolVision enhances HDD mounting bracket defect detection through advanced AI, ensuring higher standards in electronics manufacturing.

-

For repetitive manual tasks such as in this case, an automated visual inspection can help identify defective products and improve workforce efficiency.

-

SolVision optimizes PCB assembly inspection with AI, enhancing accuracy, reducing errors, and boosting efficiency with our rapid learning AI vision system.

-

Using OCR with AI deep learning, SolVision reads and detects various text and number defects on printed labels, enhancing electronics product label inspection.