Petrochemicals, Plastics, and Rubber

-

SolVision’s AI and OCR technology enhances Tire Identification Number inspection, improving accuracy, efficiency, and quality control in tire production.

-

AccuPick AI optimizes rubber compound bin picking in tire production with seamless integration and bin collision avoidance for enhanced material handling.AccuPickAutomotiveBin PickingCase StudiesPetrochemicalsPlasticsand RubberPick and Place

-

SolVision’s AI-powered vision system enhances defect detection in carbon fiber fabric inspection, adapting to lighting conditions for improved quality control.SolVisionCase StudiesClassificationDefect DetectionPetrochemicalsPlasticsand Rubber

-

META-aivi AR + AI real-time SOP validation improves plastic production for a performance materials company, boosting efficiency and reducing downtime.META-aiviCase StudiesPetrochemicalsPlasticsand RubberSOP Validation

-

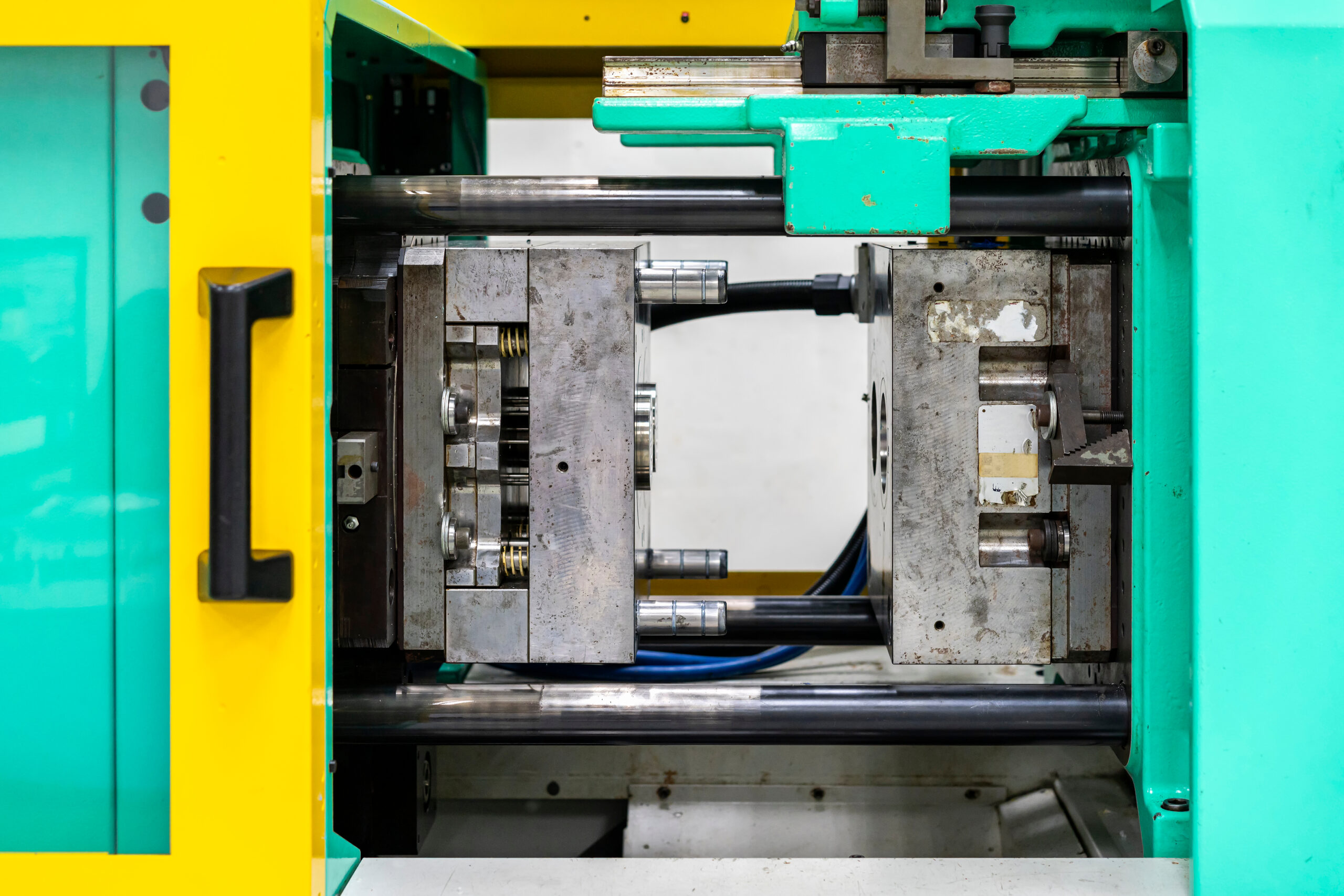

META-aivi optimizes plastic injection molding with automated machine malfunction detection and monitoring to enhance efficiency, reduce downtime, and cut costs.META-aiviAutomotiveCase StudiesPetrochemicalsPlasticsand RubberRemote Monitoring

-

Explore META-aivi’s impact on plastics manufacturing, achieving 70% faster gauge meter readings, automated data uploads, and reduced meter reading errors.

-

Solomon’s AccuPick solution enhances bin picking precision by integrating powerful software with the SolScan 3D camera, enabling precise recalibration and facilitating complete task automation.Case StudiesAccuPickBin PickingManufacturingPetrochemicalsPlasticsand Rubber

-

META-aivi uses AI detection to perform a step-by-step inspection of the chemical tanker loading/unloading process to ensure the operator is following the correct procedure.