Product Case Studies

-

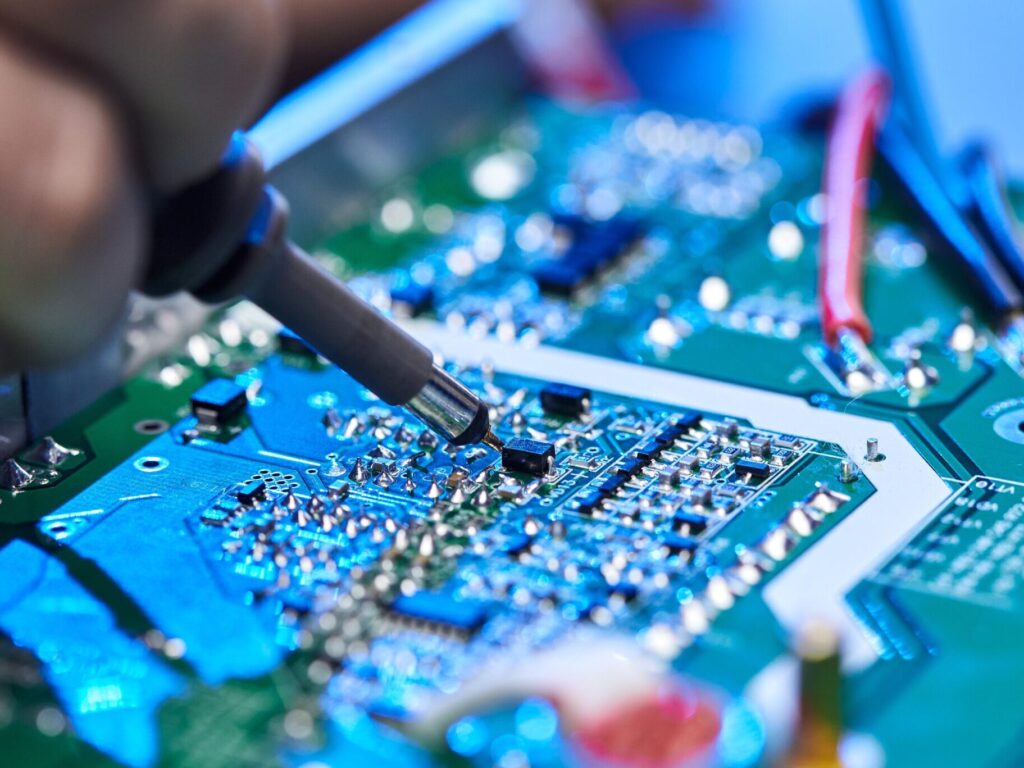

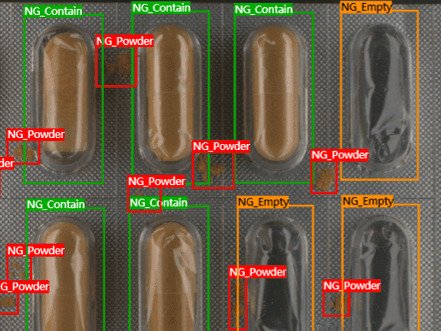

SolVision AI enhances Multilayer Ceramic Capacitor (MLCC) defect detection, reducing false rejections and improving quality control in electronics production.

-

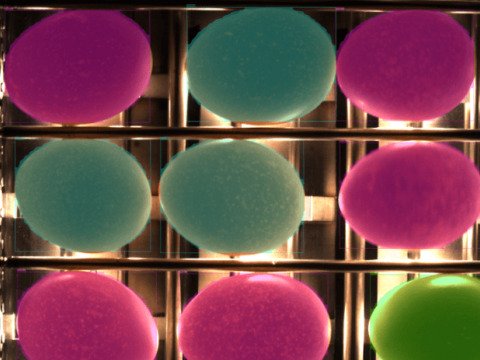

SolVision enhances cookies quality with AI-powered quality inspection, ensuring consistent appearance and high detection accuracy in snack food production.

-

SolVision AI enhances defect detection in metal gaskets, improving inspection efficiency and ensuring high-quality gasket performance.

-

SolVision deployed for woven fabric defect detection achieves precise defect identification in textiles using Solomon’s rapid AI vision technology.

View more

-

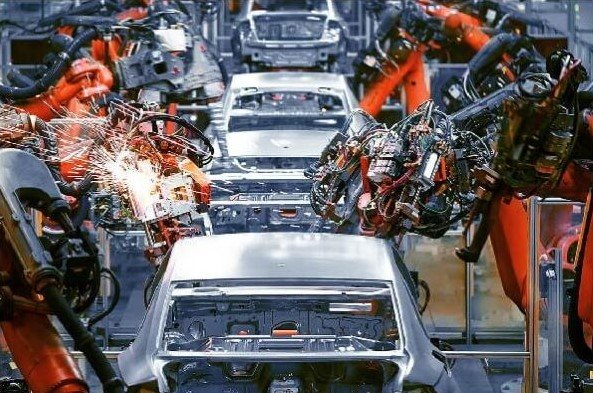

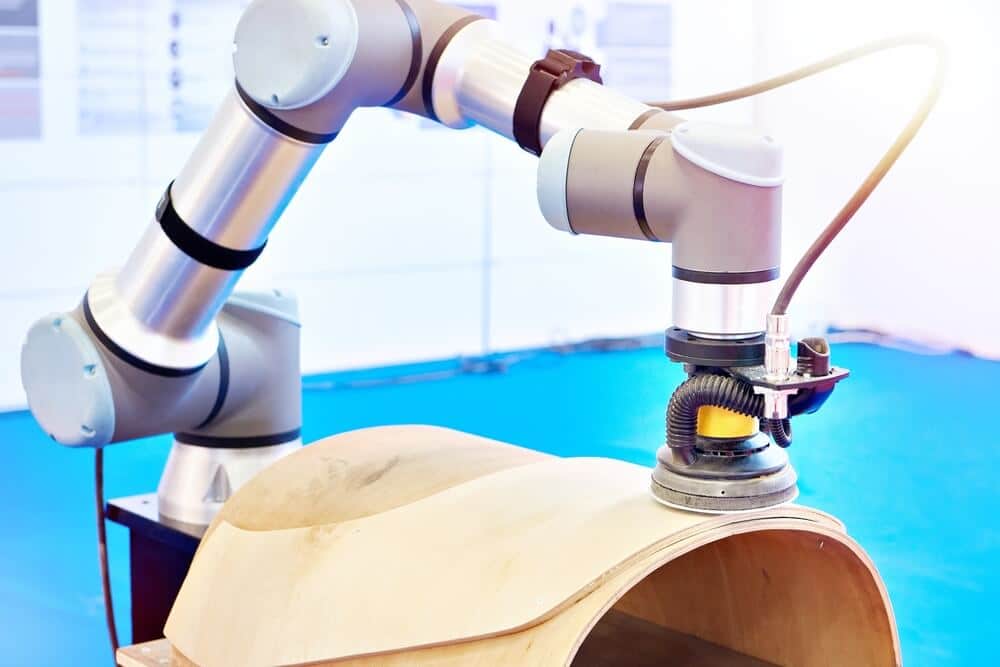

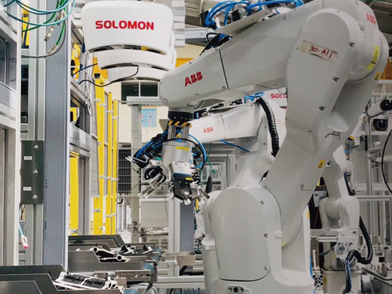

SolMotion combines AI and vision-guided robotics for precise body panel sealing, enhancing quality and efficiency in automotive manufacturing.

-

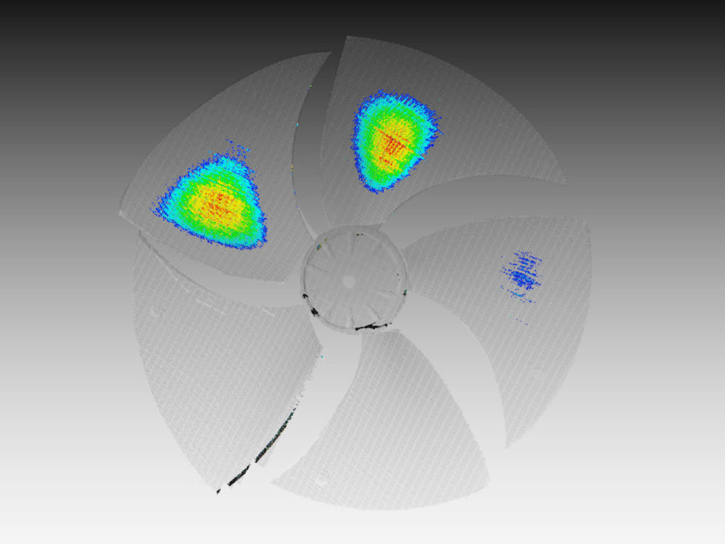

SolMotion vision guided robotics enables AI-driven automation of rail edge trimming, enhancing efficiency and supply in railway manufacturing.

-

SolMotion AI optimizes automotive assembly by detecting randomly placed auto parts with precision, regardless of orientation, using vision guided robotics.

-

SolMotion offers precise and continuous laser marking with AI-based 3D scanning technology, enabling real-time part positioning for robots to identify and mark objects accurately.

View more

-

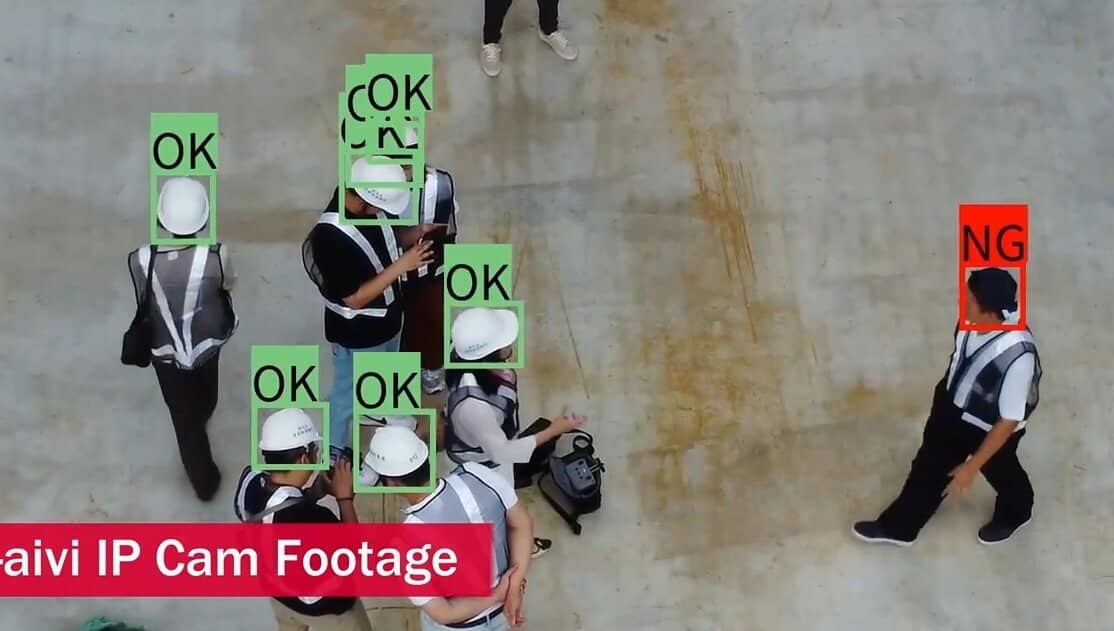

META-aivi uses AI for real-time package contents verification, enhancing accuracy, reducing errors, and ensuring superior packing quality control.

-

META-aivi AR + AI enhances air compressor inspection and maintenance with real-time SOP validation, ensuring compliance and digital record-keeping.

-

META-aivi’s AR + AI solution enhances tube counting accuracy and efficiency for bicycle frame production, reducing errors and boosting productivity.

-

META-aivi AR + AI real-time SOP validation improves plastic production for a performance materials company, boosting efficiency and reducing downtime.

View more

-

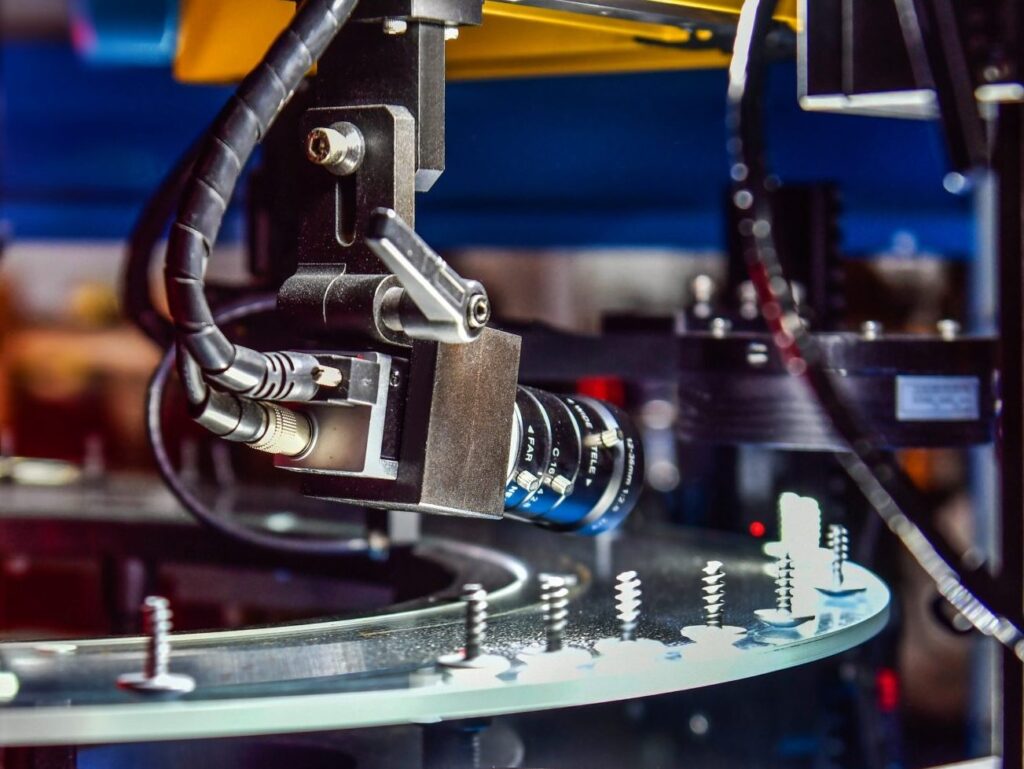

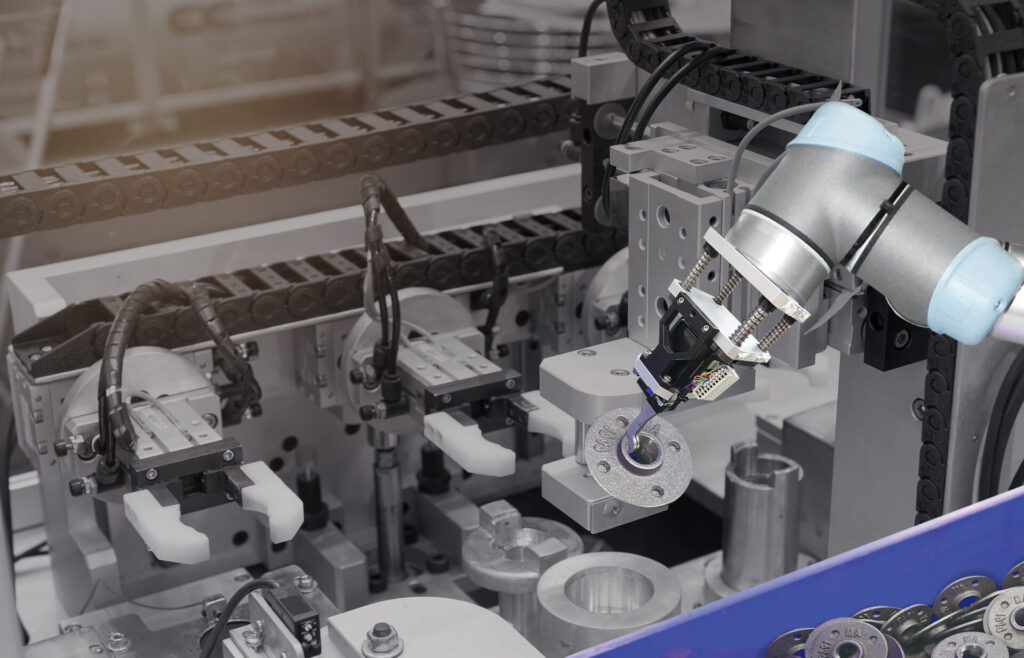

AccuPick + SolScan enhance bin picking for a European auto parts manufacturer, cutting cycle time to 1.6 seconds and boosting efficiency with rapid AI training.

-

AccuPick AI optimizes rubber compound bin picking in tire production with seamless integration and bin collision avoidance for enhanced material handling.

-

Discover how Solomon’s AccuPick optimized automated packing with AI to assemble 300,000 NDP packs, boosting efficiency and reducing labor by 50%.

-

AccuPick streamlines automated mixed depalletizing for a leading home appliances manufacturer with the speed and precision of our AI vision technology.

View more

Industry Case Studies

Application Case Studies

All Case Studies

-

SolMotion combines AI and vision-guided robotics for precise body panel sealing, enhancing quality and efficiency in automotive manufacturing.

-

AccuPick + SolScan enhance bin picking for a European auto parts manufacturer, cutting cycle time to 1.6 seconds and boosting efficiency with rapid AI training.

-

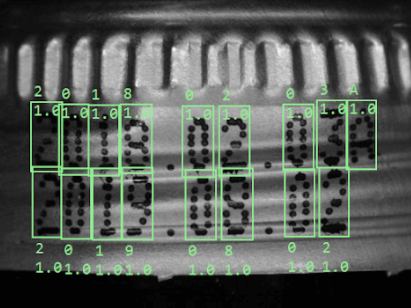

SolVision AI enhances Multilayer Ceramic Capacitor (MLCC) defect detection, reducing false rejections and improving quality control in electronics production.

-

SolVision enhances cookies quality with AI-powered quality inspection, ensuring consistent appearance and high detection accuracy in snack food production.

-

SolVision AI enhances defect detection in metal gaskets, improving inspection efficiency and ensuring high-quality gasket performance.

-

SolVision deployed for woven fabric defect detection achieves precise defect identification in textiles using Solomon’s rapid AI vision technology.

-

SolVision utilizes deep learning technology for enhanced surgical mask inspection, ensuring accurate defect detection and improved quality control.

-

SolVision’s AI and OCR technology enhances Tire Identification Number inspection, improving accuracy, efficiency, and quality control in tire production.

-

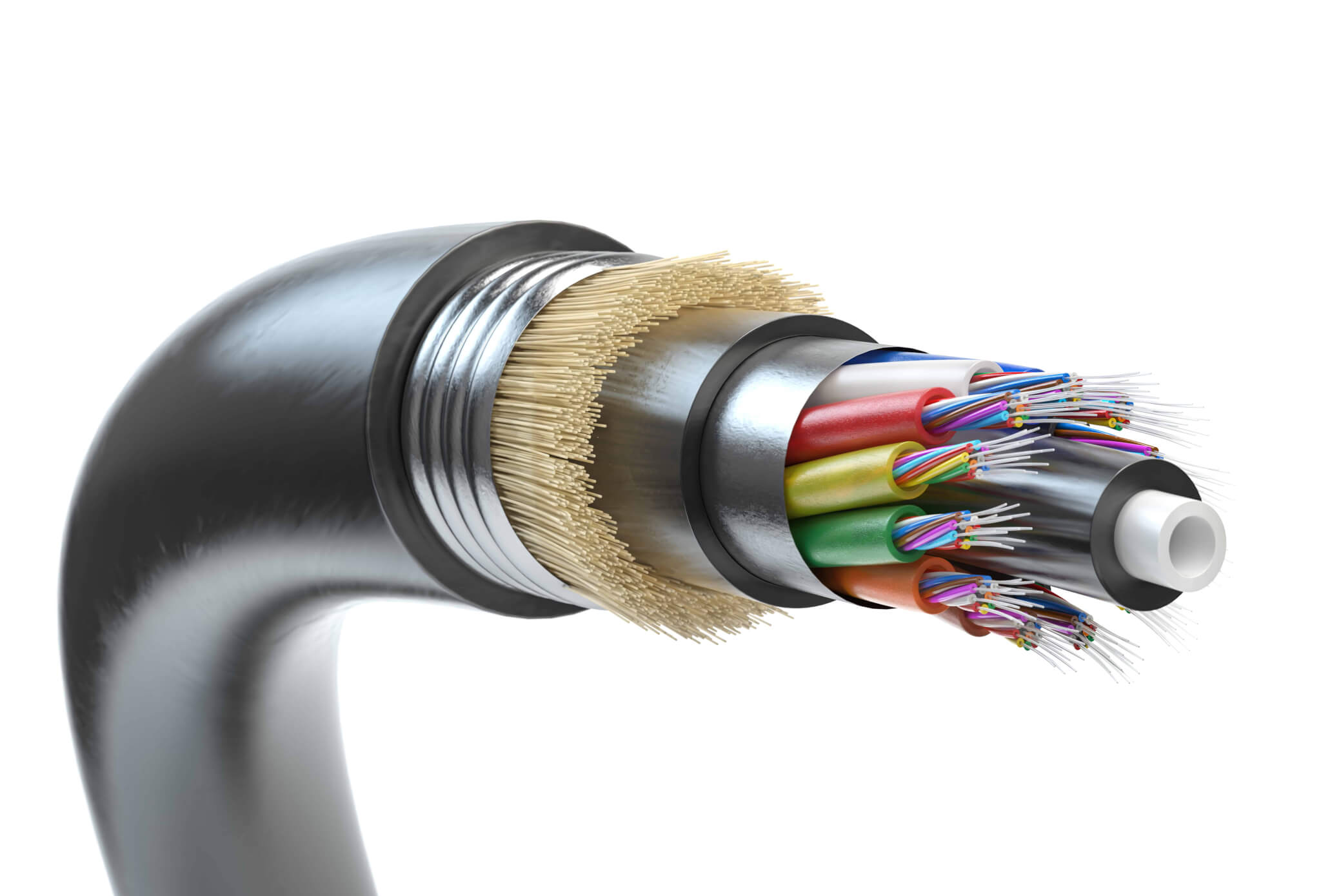

SolVision AI enhances cable defect detection, improving cable insulation quality control, inspection accuracy, and production efficiency for wires and cables.